-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

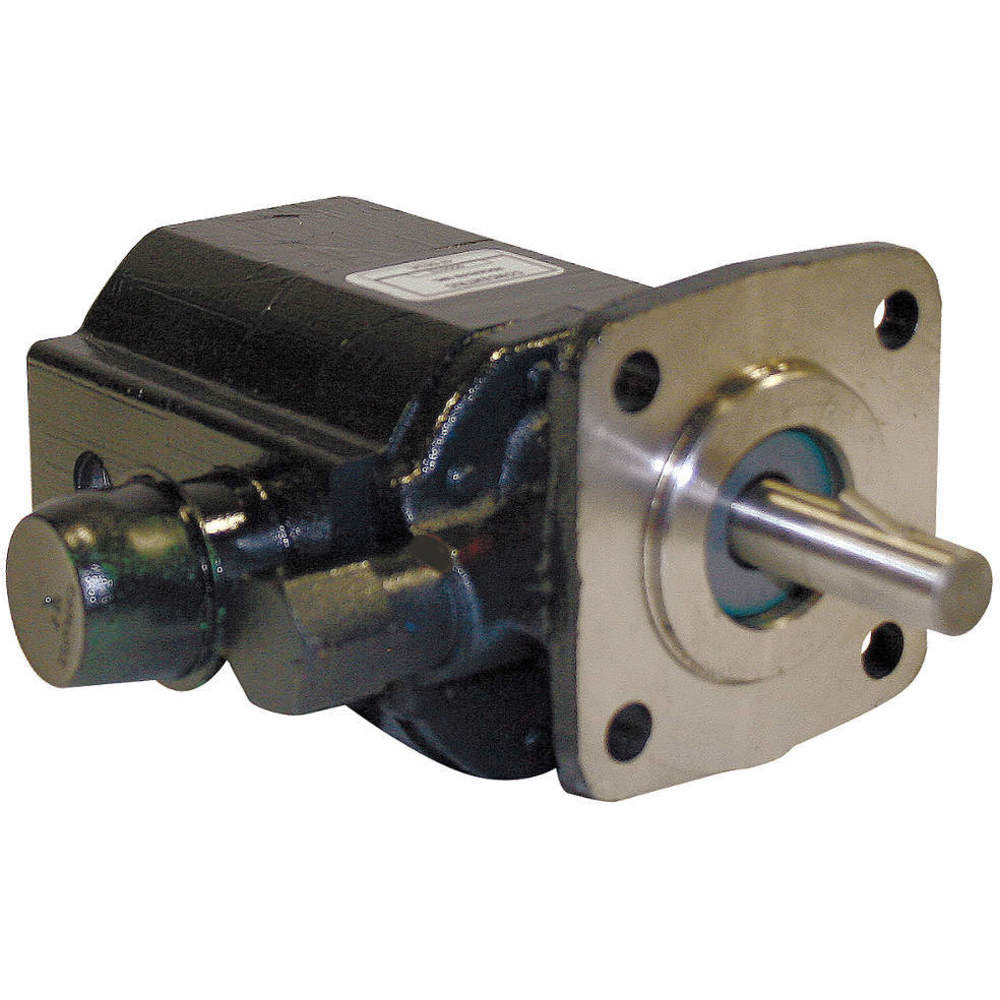

| Item | Hydraulic Gear Pump/Motor |

|---|---|

| Dimension A | 3.69" |

| Discharge Connection Size | 7/8"-14 |

| Displacement | 0.388 cu. in./rev. |

| Displacement Per Revolution | 0.388 cu. in./rev. |

| Flow Rate (maximum) | 8 GPM |

| Flow Rate (minimum) | 3 GPM |

| Gpm @ 3600 Rpm & 1000 Psi | 5 GPM |

| Housing | Cast Iron |

| Housing Material | Cast Iron |

| Intake Connection | 7/8"-14 Sae |

| Max. Continuous Pressure | 3000 psi |

| Max. Intermittent Pressure | 3300 psi |

| Max. Speed | 5000 RPM |

| Media Intake Connection Size | 7/8"-14 |

|---|---|

| Media Intake Connection Type | SAE |

| Motor Speed (maximum) | 5000 RPM |

| Motor Speed (minimum) | 1255 RPM |

| Mounting Type | 4 Bolt 4F17 |

| Nominal Gpm @ 1200 Rpm | 2 GPM |

| Overall Height | 3.3" |

| Overall Length | 5.2" |

| Overall Width | 3.3" |

| Rotation | CW/CCW |

| Shaft Extension (in.) | 1/2" x 1 1/2" |

| Shaft Outer Diameter | 1/2" |

| Shaft Type | Keyed |

| Type | Birotational |

Haldex Barnes (Concentric) 1070045 hydraulic pump is a bi-rotational pump / motor that converts mechanical power into hydraulic energy in industrial-grade hydraulic systems. It is a reliable, high-efficiency pump that delivers a smooth and continuous flow. This pump is used for belt-driven, direct drive, agricultural, material handling and construction equipment applications (in addition to robotics, machine tools and other types of machinery).

| Height (cm) | 10.67 |

|---|---|

| Length (cm) | 16 |

| Width (cm) | 10.92 |

| HS Code | 8412298015 |

|---|---|

| Country Of Origin | US |

| Weight (kg) | 2.5875 |

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)