-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

| Item | Hydraulic Cylinder |

|---|---|

| Body Material | Steel |

| Center Hole Dia. | 3/4" |

| Collar Thread Length | 1.19" |

| Collar Thread Size | 2 3/4"-16 |

| Cylinder Bore | 2.13" |

| Cylinder Type | Hollow Plunger |

| Effective Push Area | 2.76 sq. in. |

| Extended Height | 6.37" |

| Handle | No |

| Includes | Coupler, Reducer |

| Material | Steel |

| Max. Operating Pressure | 10000 psi |

| Max. Push Capacity | 12 ton. |

|---|---|

| Nominal Capacity | 12 ton. |

| Nominal Stroke Length | 2" |

| Oil Capacity Push | 4.49 cu. in. |

| Outside Dia. | 2 3/4" |

| Plunger Dia. | 1.38" |

| Plunger Type | Hollow |

| Retracted Height | 4.75" |

| Series | RCH Series |

| Single Acting/double Acting | Single Acting |

| Stroke Length | 1 5/8" |

| Weighing Capacity | 12 ton. |

Enerpac RCH121 single-acting, hollow plunger hydraulic cylinder is ideal for construction, manufacturing and maintenance applications. It is used in tasks that require lifting heavy loads, pushing or pulling objects and providing controlled force.

| Height (cm) | 10.16 |

|---|---|

| Length (cm) | 12.7 |

| Width (cm) | 15.24 |

| HS Code | 8431100090 |

|---|---|

| Country Of Origin | CN |

| Weight (kg) | 2.79 |

Major factors include required load capacity, material & construction, operating pressure, mounting options and stroke length.

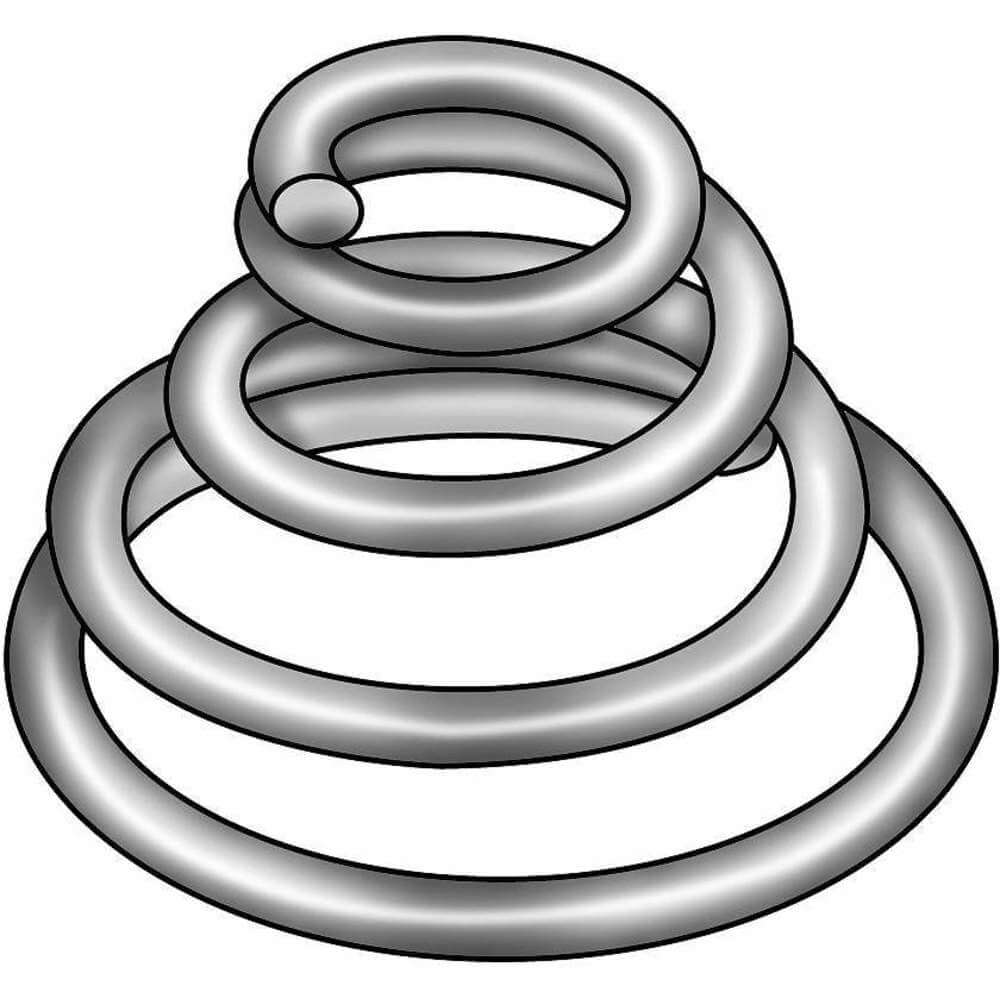

The single-acting spring return mechanism ensures that when the hydraulic pressure is released, the plunger retracts smoothly and promptly to its initial position, promoting efficient and dependable operation.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)