-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

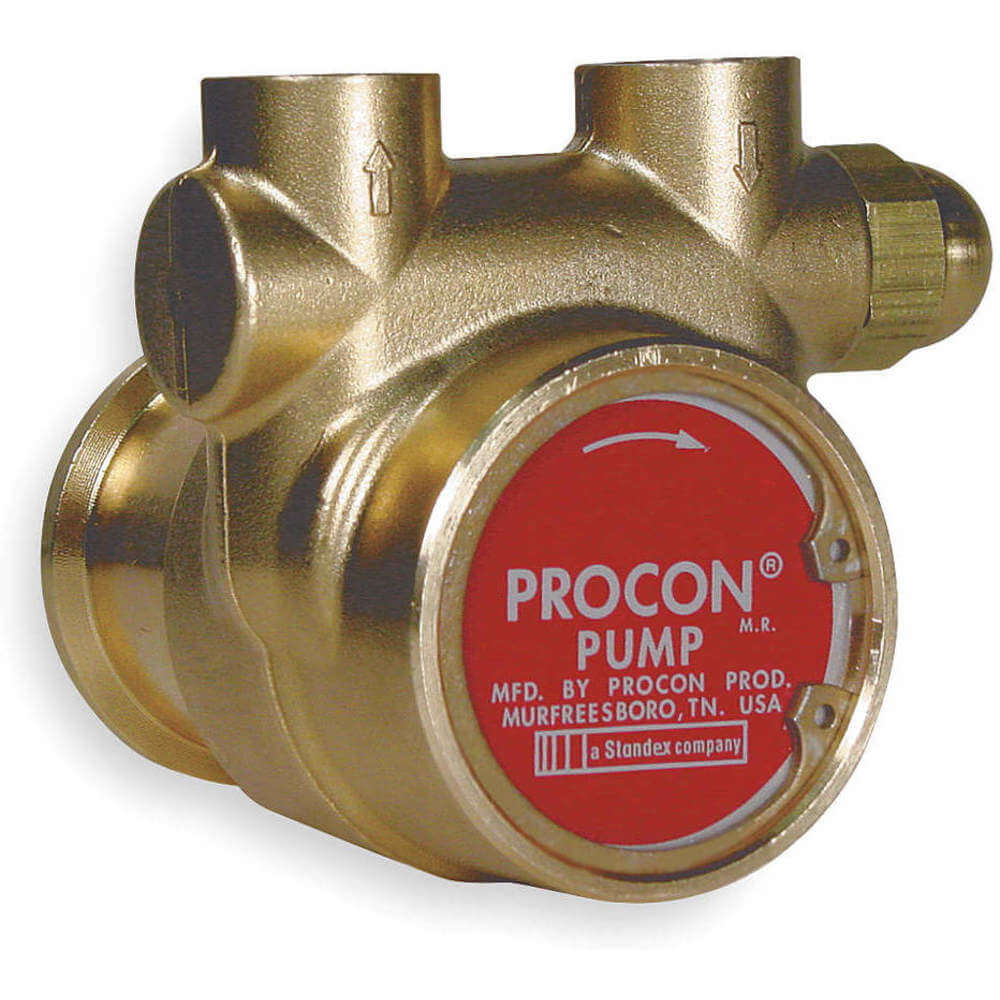

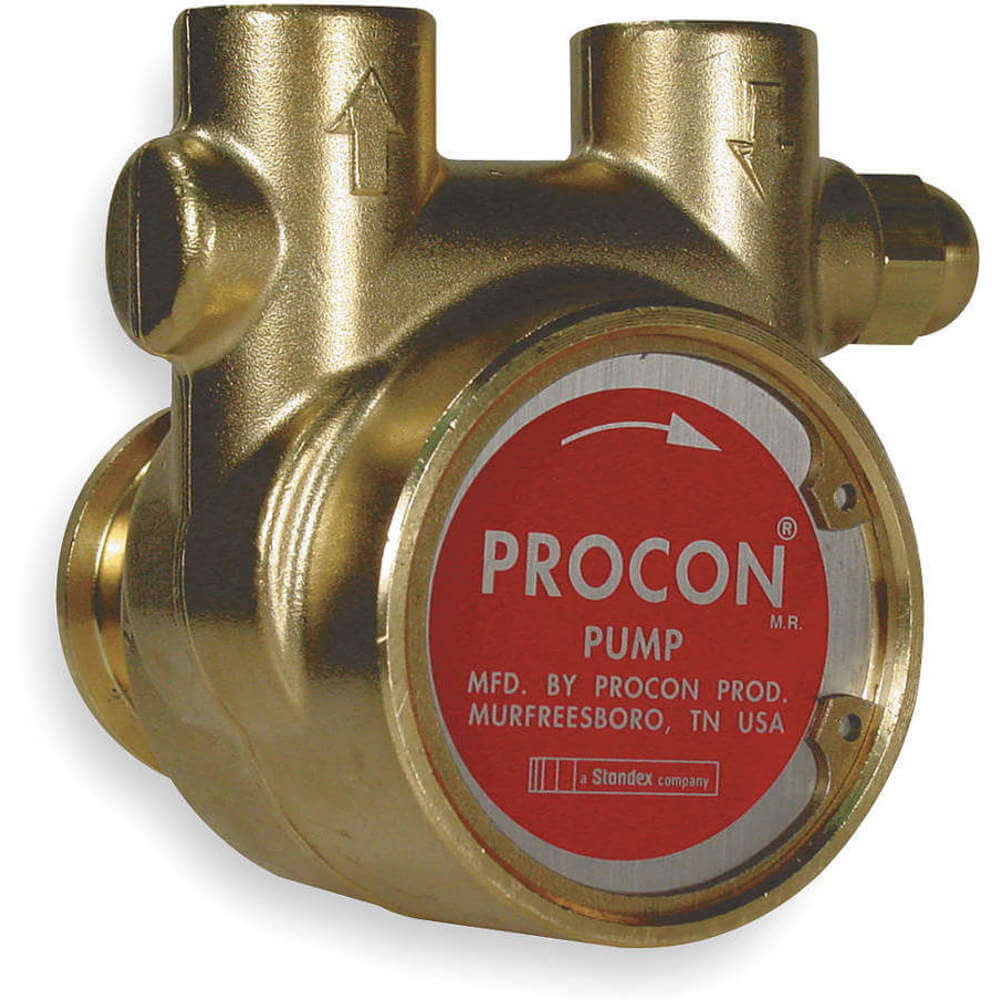

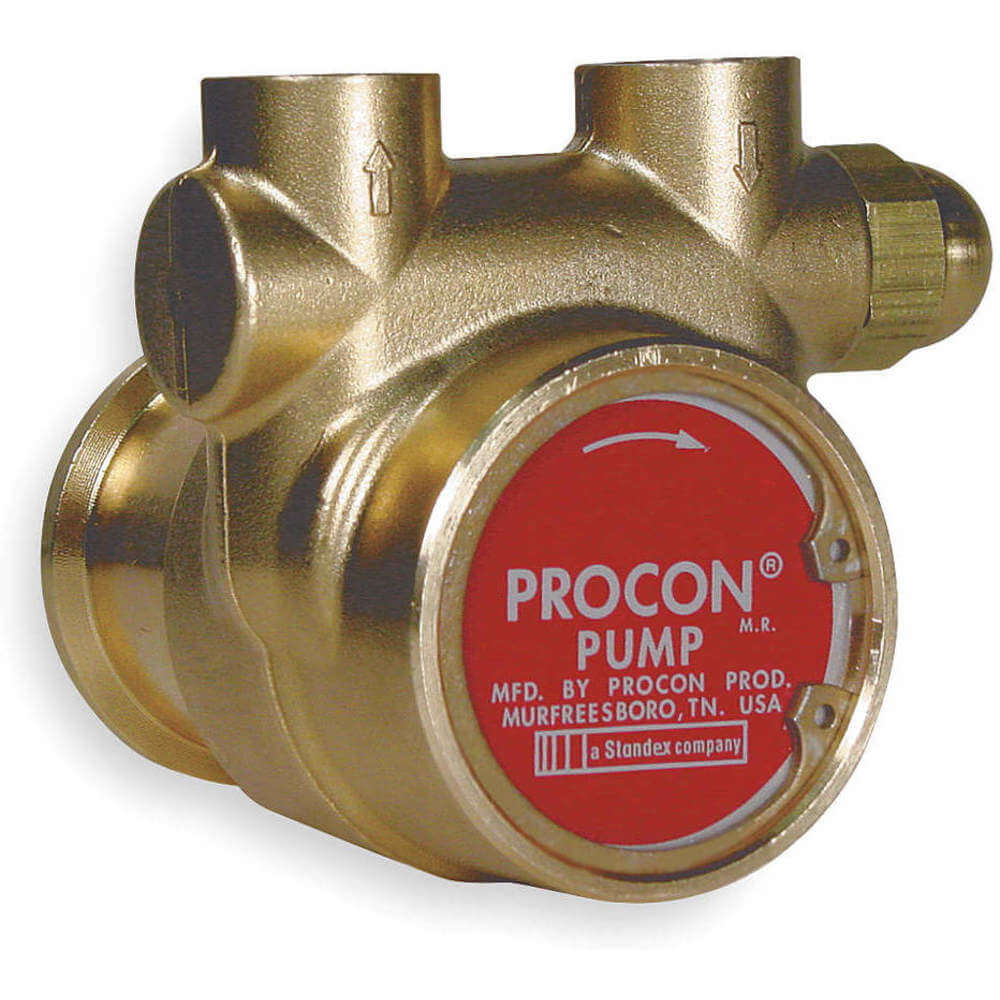

| Item | Rotary Vane Pump |

|---|---|

| Body Material | Brass |

| Built-in | Relief Valve |

| Bypass Included | Yes |

| Compatible Motor Frame | 48Y NEMA |

| Drive | 0.118" Double Flat |

| Dry Suction Lift | 3.3 ft. |

| Dry Weight | 2.5 lbs. |

| External Relief | Not Required |

| Filter | Not Included |

| Filter Combined | No |

| Filter Included | No |

| Flow Rate @ 100 Psi | 60 GPH |

| Flow Rate @ 150 Psi | 58 GPH |

| Flow Rate @ 200 Psi | 56 GPH |

| Flow Rate @ 250 Psi | 54 GPH |

| Flow Rate @ 50 Psi | 62 GPH |

| For Media Type | No |

| Frame | 48Y NEMA |

| Grade | Grade 303 |

| Height | 3" |

| Hp | 7/20 hp |

| Hp @ 100 Psi | 1/4 hp |

| Hp @ 150 Psi | 1/4 hp |

| Hp @ 200 Psi | 1/3 hp |

| Hp @ 250 Psi | 1/2 hp |

| Hp @ 50 Psi | 1/4 hp |

| Includes | Relief Valve |

| Includes Filter | No |

| Includes Strainer | Without |

| Inlet Size | 3/8" |

| Inlet Type | FNPT |

| Length | 3.3" |

| Max. Feet Of Head | 6 ft. Of Head |

| Max. Flow Rate | 60 GPH |

| Max. Head | 6 ft. |

| Max. Motor Speed | 2400 RPM |

| Max. Operating Pressure | 150 psi |

| Max. Operating Temp. | 160°F |

| Max. Relief Pressure | 250 psi |

| Max. Viscosity | 100 cPS |

|---|---|

| Media Type | No |

| Min. Flow Rate | 54 GPH |

| Min. Operating Temp. | -4°F |

| Min. Rpm | 1000 RPM |

| Mounting | Carbonator Mount |

| Mounting Type | Carbonator Clamp |

| Noise Level | 60 dBA |

| Nsf 169 Listed | Yes |

| Nsf Certified | Yes |

| Operating Temp. Range | -4°F to +160°F |

| Outlet Size | 3/8" |

| Outlet Type | FNPT |

| Overall Height | 3" |

| Overall Length | 3.3" |

| Overall Width | 3.9" |

| Ph Range | 6 pH |

| Port Connection Size | 3/8" |

| Port Connection Type | NPT |

| Relief Valve | Yes |

| Relief Valve Pressure | 200 psi |

| Rotation | Clockwise |

| Rotor Material | Stainless Steel |

| Seal Material | Carbon, Ceramic |

| Self Priming Wet | 6 ft. |

| Series | 2 Series |

| Shaft | 1/2" Stainless Steel |

| Shaft Combined | 1/2" 303 Stainless Steel |

| Shaft Material | Stainless Steel |

| Shaft Outside Dia. | 1/2" |

| Static Pressure | 100 psi |

| Strainer Area | 3.25 sq. in. |

| Tds Resolution | 5000 ppm |

| Valve Configuration | Balanced External Adjust |

| Valve Type | Bypass Ultem |

| Vane Material | Carbon |

| Wet Suction Lift | 6.6 ft. |

| Width | 3.9" |

| Standards | NSF, ROHS |

Procon 112A060F11CA rotary vane pump is used in beverage dispensing systems, soda fountains and coffee machines to handle liquids efficiently and maintain a consistent flow rate. This pump can handle a wide range of viscosities and is designed for continuous operation, making them reliable for commercial settings.

| Height (cm) | 9.8 |

|---|---|

| Length (cm) | 7.67 |

| Width (cm) | 8.48 |

| HS Code | 8413500090 |

|---|---|

| Country Of Origin | US |

| Weight (kg) | 0.945 |

This pump has a maximum operating pressure of 150 psi.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)