-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

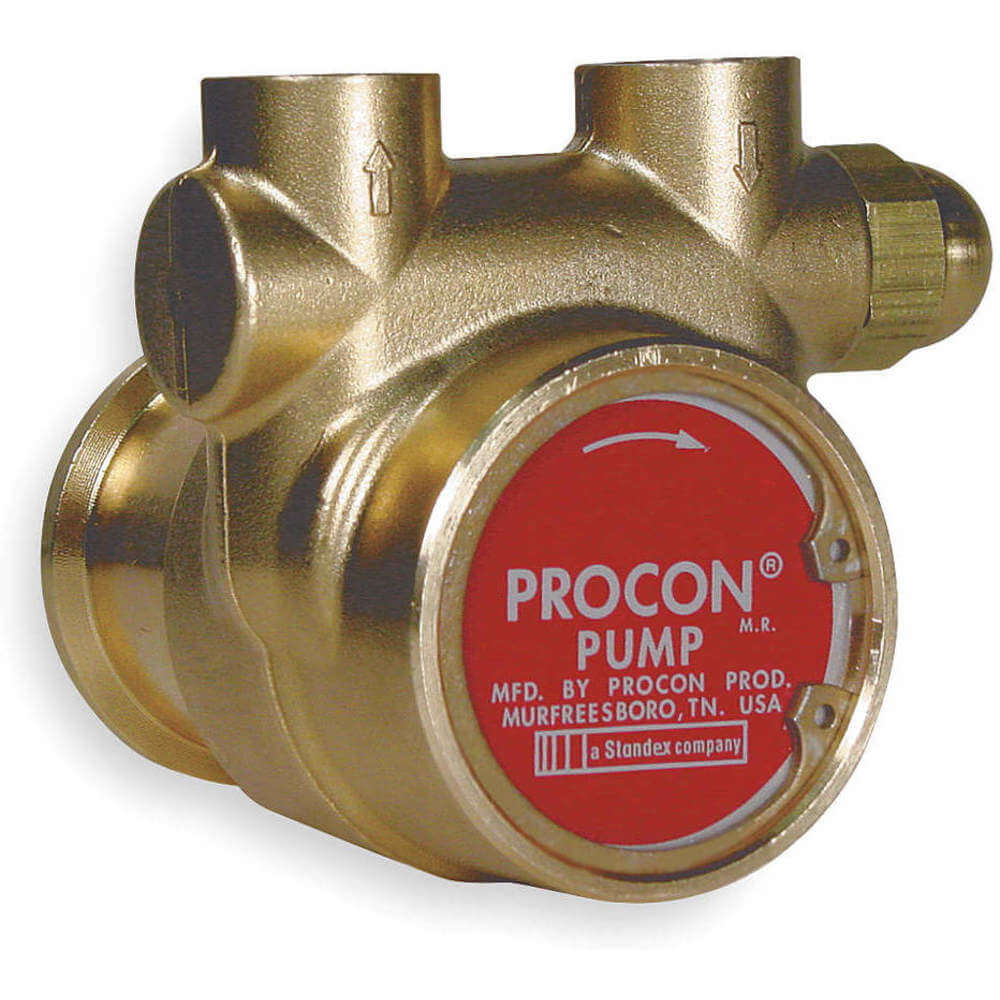

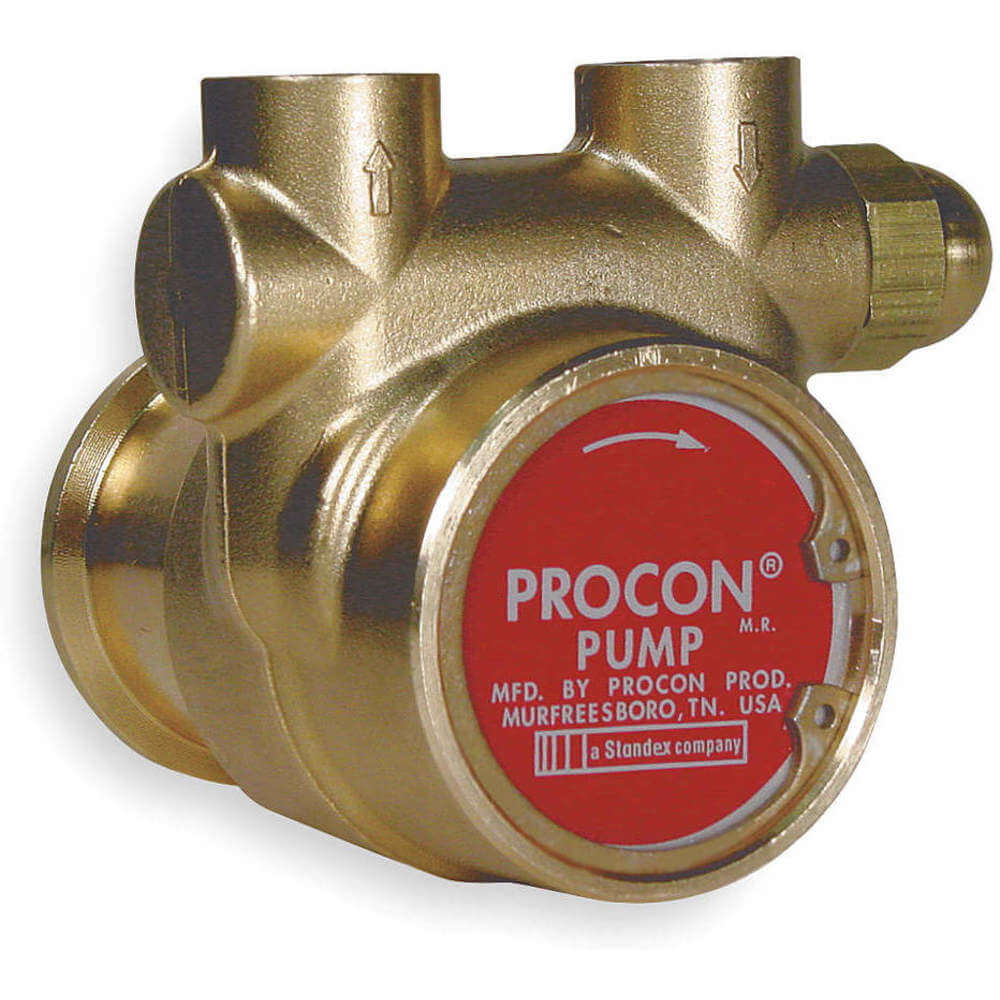

| Item | Rotary Vane Pump |

|---|---|

| Body Material | Brass |

| Built-in | Relief Valve |

| Bypass Included | Yes |

| Compatible Motor Frame | 48Y NEMA |

| Drive | Slotted With Bronze Coupling 1143 |

| Dry Suction Lift | 3.3 ft. |

| Dry Weight | 4.5 lbs. |

| External Relief | Not Required |

| Filter | Not Included |

| Filter Combined | No |

| Filter Included | No |

| Flow Rate @ 100 Psi | 190 GPH |

| Flow Rate @ 150 Psi | 186 GPH |

| Flow Rate @ 200 Psi | 182 GPH |

| Flow Rate @ 250 Psi | 178 GPH |

| Flow Rate @ 50 Psi | 193 GPH |

| For Media Type | No |

| Frame | 48Y NEMA |

| Grade | Grade 303 |

| Height | 3 4/5" |

| Hp | 3/4 hp |

| Hp @ 100 Psi | 1/3 hp |

| Hp @ 150 Psi | 1/5 hp |

| Hp @ 200 Psi | 3/4 hp |

| Hp @ 250 Psi | 3/4 hp |

| Hp @ 50 Psi | 1/4 hp |

| Includes | Relief Valve |

| Includes Filter | No |

| Inlet Size | 1/2" |

| Inlet Type | FNPT |

| Length | 4.1" |

| Max. Feet Of Head | 6 ft. Of Head |

| Max. Flow Rate | 190 GPH |

| Max. Head | 6 ft. |

| Max. Motor Speed | 2400 RPM |

| Max. Operating Pressure | 150 psi |

| Max. Operating Temp. | 160°F |

| Max. Relief Pressure | 250 psi |

|---|---|

| Max. Viscosity | 100 cPS |

| Media Type | No |

| Min. Flow Rate | 178 GPH |

| Min. Operating Temp. | -4°F |

| Min. Rpm | 1000 RPM |

| Mounting | Carbonator Mount |

| Mounting Type | Carbonator Clamp |

| Noise Level | 60 dBA |

| Nsf 169 Listed | Yes |

| Nsf Certified | Yes |

| Operating Temp. Range | -4°F to +160°F |

| Outlet Size | 1/2" |

| Outlet Type | FNPT |

| Overall Height | 3 4/5" |

| Overall Length | 4.1" |

| Overall Width | 3 4/5" |

| Ph Range | 6 pH |

| Port Connection Size | 1/2" |

| Port Connection Type | NPT |

| Relief Valve | Yes |

| Relief Valve Pressure | 200 psi |

| Rotation | Clockwise |

| Rotor Material | Stainless Steel |

| Seal Material | Carbon, Ceramic |

| Series | 4 Series |

| Shaft | 1/2" Stainless Steel |

| Shaft Combined | 1/2" 303 Stainless Steel |

| Shaft Material | Stainless Steel |

| Shaft Outside Dia. | 1/2" |

| Static Pressure | 100 psi |

| Tds Resolution | 5000 ppm |

| Valve Configuration | Standard Non External Adjust |

| Valve Type | Solid Ultem |

| Vane Material | Carbon |

| Wet Suction Lift | 6.6 ft. |

| Width | 3 4/5" |

| Standards | NSF, ROHS |

Procon 114B190F11BA rotary vane pump is a positive displacement pump used in various industrial and commercial applications, making it suitable for pumping liquids in beverage dispensers, espresso machines and water filtration systems.

| Height (cm) | 10.97 |

|---|---|

| Length (cm) | 9.73 |

| Width (cm) | 10.41 |

| HS Code | 8413500090 |

|---|---|

| Country Of Origin | US |

| Weight (kg) | 1.4895 |

While operating a rotary vane pump, use protective equipment when necessary, ensure proper grounding and avoid exposure to hazardous substances.

The maximum mechanical horsepower required for the pump is 0.75 hp (559W).

Running the pump dry for an extended period can cause damage. It is recommended to avoid running the pump without fluid, as it may lead to premature wear or failure of internal components.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)