-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

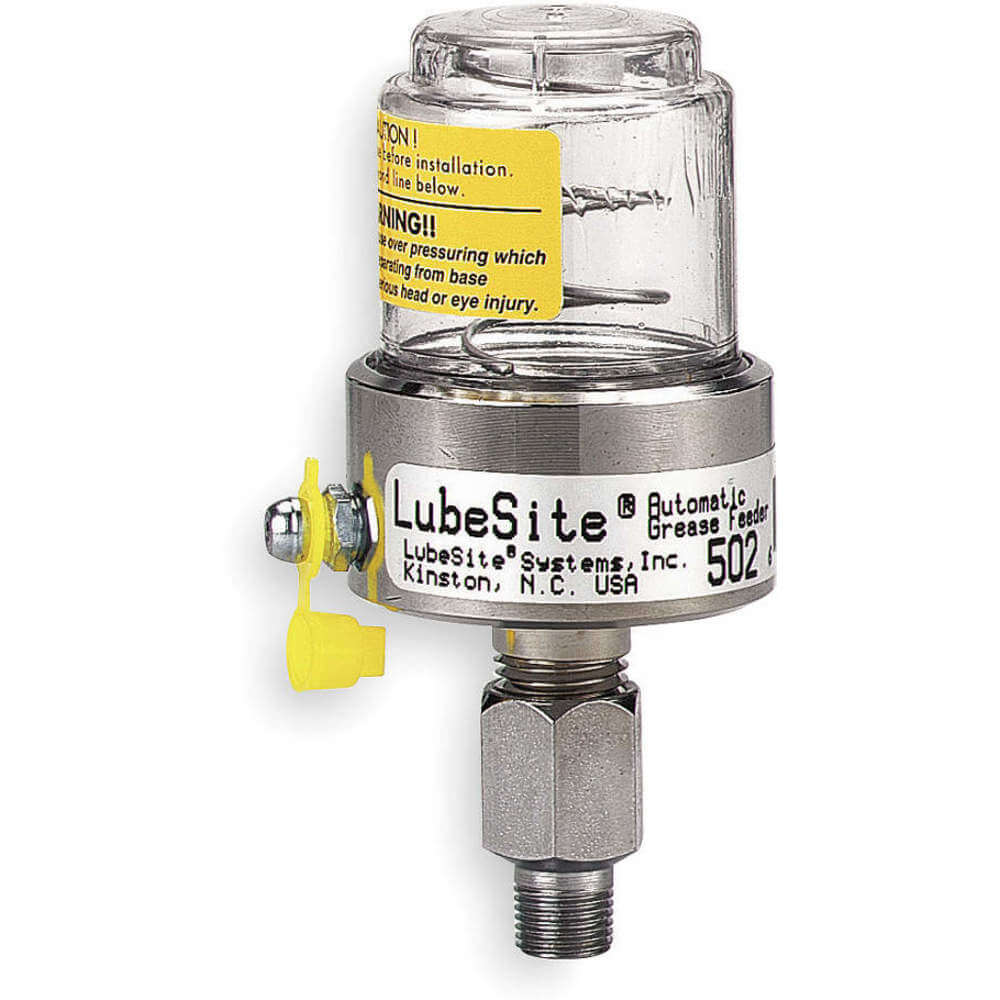

| Item | Grease Feeder |

|---|---|

| Base Material | Aluminum |

| Cap Material | Stainless Steel |

| Capacity | 4 oz. |

| Connection Size | 1/8" |

| Connection Type | NPT |

| Delivery Method | Continuous |

| Feeder Capacity | 4 fl. oz. |

| Feeder Material | Aluminum |

| Fill | Zerk |

| Finish | Anodized |

| Flow Rate Adjustability | Non Adjustable |

| Grease Color | Yellow |

| Height | 7 1/8" |

|---|---|

| Includes | Springs |

| Lubrication Point Type | Single |

| Material | Tempered Borosilicate Glass |

| Max. Operating Temperature | 450°F |

| Min. Operating Temperature | -10°F |

| Operating Temp. | -10°F to +450°F |

| Overall Diameter | 3 1/4" |

| Overall Height | 7 1/8" |

| Refillable | Yes |

| Spring Force | 9.1 psi |

| Thread Size | 1/8" |

LubeSite 704 grease feeder allows precise dispensing of the grease to a bearing and other critical moving components in ambient temperatures up to 450 degrees F. It is ideal for application in steel mills, glass plants, lumber drying kilns, nuclear environments and metal treating settings.

| Height (cm) | 11.18 |

|---|---|

| Length (cm) | 21.84 |

| Width (cm) | 11.18 |

| HS Code | 8479899899 |

|---|---|

| Country Of Origin | CN |

| Weight (kg) | 0.855 |

LubeSite lubricant feeders use the Venturi effect that allows a reduction in the fluid pressure that occurs due to fluid flowing through a constricted section of a pipe.

LubeSite single-point lubricators are mounted on machines / equipment requiring frequent lubrication. These automatic grease feeders dispense only the required amount of lubricant at short intervals. They further prevent machine failures due to over or under-greasing which may cause breakdowns and lost productivity.

If LubeSite 704 grease feeder is overfilled, it may cause over-pressure that may lead to separation of the top from the base that may cause serious damage to the head / eye.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)