-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

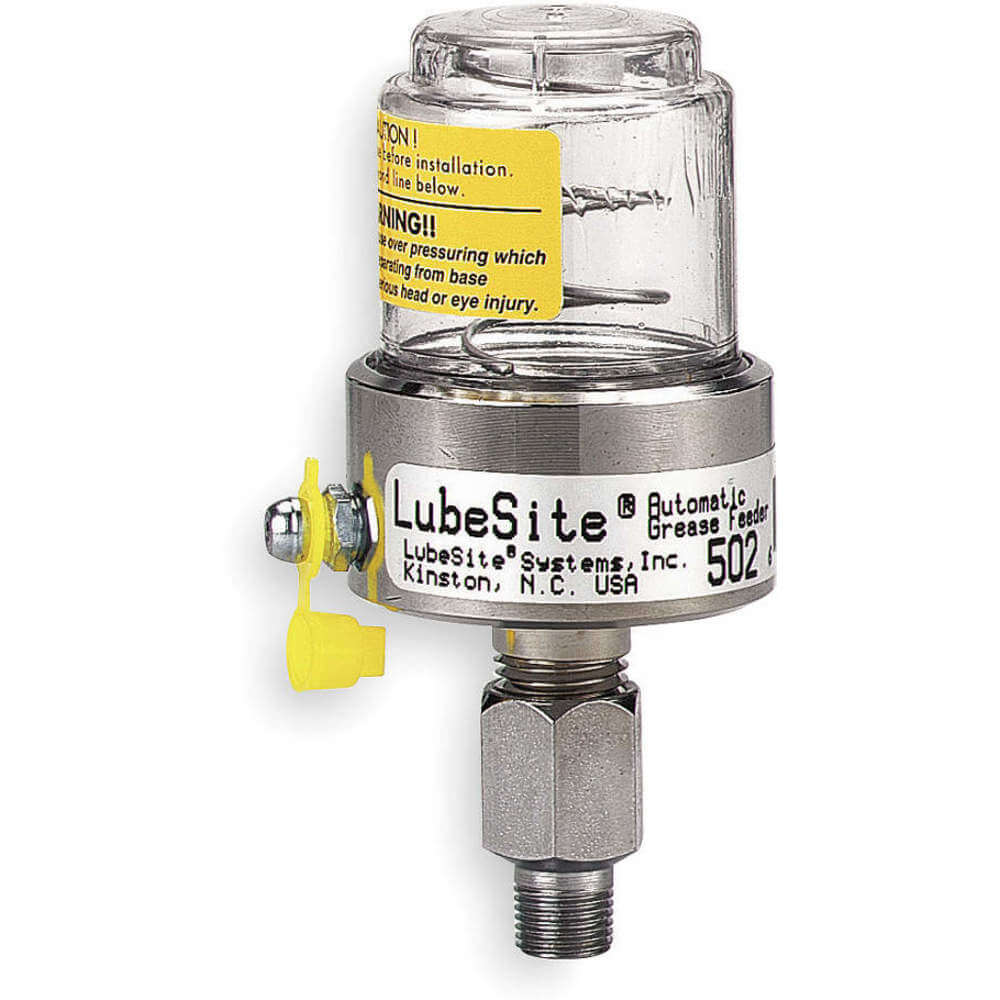

| Item | Grease Feeder |

|---|---|

| Capacity | 2 oz. |

| Connection Size | 1/8" |

| Connection Type | NPT |

| Delivery Method | Continuous |

| Feeder Capacity | 2 fl. oz. |

| Feeder Material | Aluminum |

| Fill | Zerk |

| Finish | Nickel Chrome Plated |

| Flow Rate Adjustability | Non Adjustable |

| Grease Color | Red |

| Height | 4 5/8" |

| Includes | Springs |

|---|---|

| Lubrication Point Type | Single |

| Material | Polycarbonate |

| Max. Operating Temperature | 250°F |

| Min. Operating Temperature | -10°F |

| Operating Temp. | -10°F to +250°F |

| Overall Diameter | 2 3/8" |

| Overall Height | 4 5/8" |

| Refillable | Yes |

| Spring Force | 14.5 psi |

| Thread Size | 1/8" |

LubeSite 505 corrosion-resistant grease feeder can be mounted to machines & equipment to automatically dispense grease into moving machine components. It is ideal for maintaining proper grease levels without the need for manual checks. It prevents machine failure due to over or under-greasing, which can lead to a sloppy mess / breakdowns / loss of productivity. This unit keeps the bearings on motors, conveyors, fans and other critical machine parts lubricated.

| Height (cm) | 8.38 |

|---|---|

| Length (cm) | 13.97 |

| Width (cm) | 10.92 |

| HS Code | 3923900080 |

|---|---|

| Country Of Origin | CN |

| Weight (kg) | 0.315 |

LubeSite 900 Grease Refill Kits: They work with all polycarbonate and high-temperature grease feeders. The kits include all required fittings and 10 ft of high-pressure polyethylene tubing.

This model can be used with any NLGI 0 to 4 non-separating grease.

Do not overfill it as it can cause over-pressure, which can lead to separation of the top from the base, and hence, serious head or eye injury.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)