-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

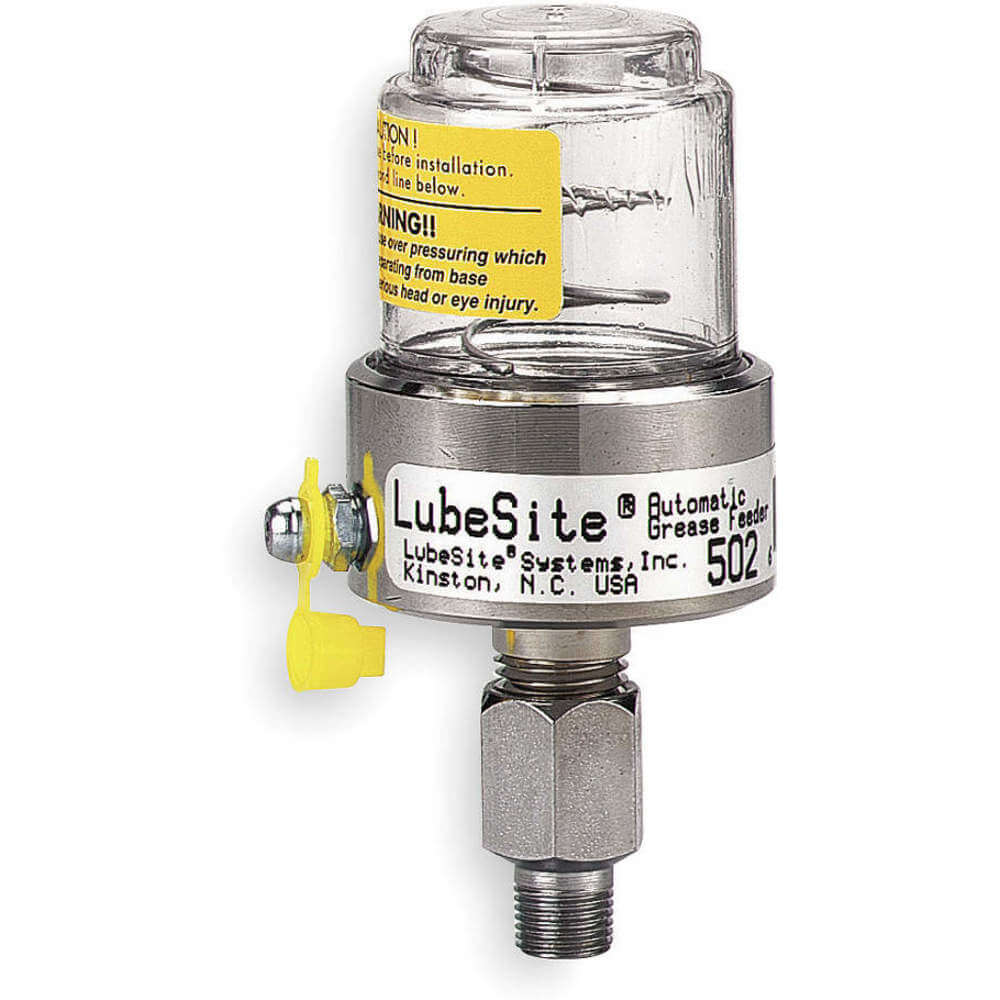

| Item | Grease Feeder |

|---|---|

| Base Material | Aluminum |

| Capacity | 2 oz. |

| Connection Size | 1/8" |

| Connection Type | NPT |

| Delivery Method | Continuous |

| Feeder Capacity | 2 fl. oz. |

| Feeder Material | Aluminum |

| Fill | Zerk |

| Finish | Anodized |

| Flow Rate Adjustability | Non Adjustable |

| Grease Color | Red |

| Height | 4 5/8" |

|---|---|

| Includes | Springs |

| Lubrication Point Type | Single |

| Material | Polycarbonate |

| Max. Operating Temperature | 250°F |

| Min. Operating Temperature | -10°F |

| Operating Temp. | -10°F to +250°F |

| Overall Diameter | 2 3/8" |

| Overall Height | 4 5/8" |

| Refillable | Yes |

| Spring Force | 14.5 psi |

| Thread Size | 1/8" |

LubeSite 305 grease feeder is used for keeping bearings lubricated on conveyors, fans and motors.

| Height (cm) | 11.75 |

|---|---|

| Length (cm) | 6.03 |

| Width (cm) | 6.03 |

| HS Code | 8487900080 |

|---|---|

| Country Of Origin | CN |

| Weight (kg) | 0.2925 |

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)