-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

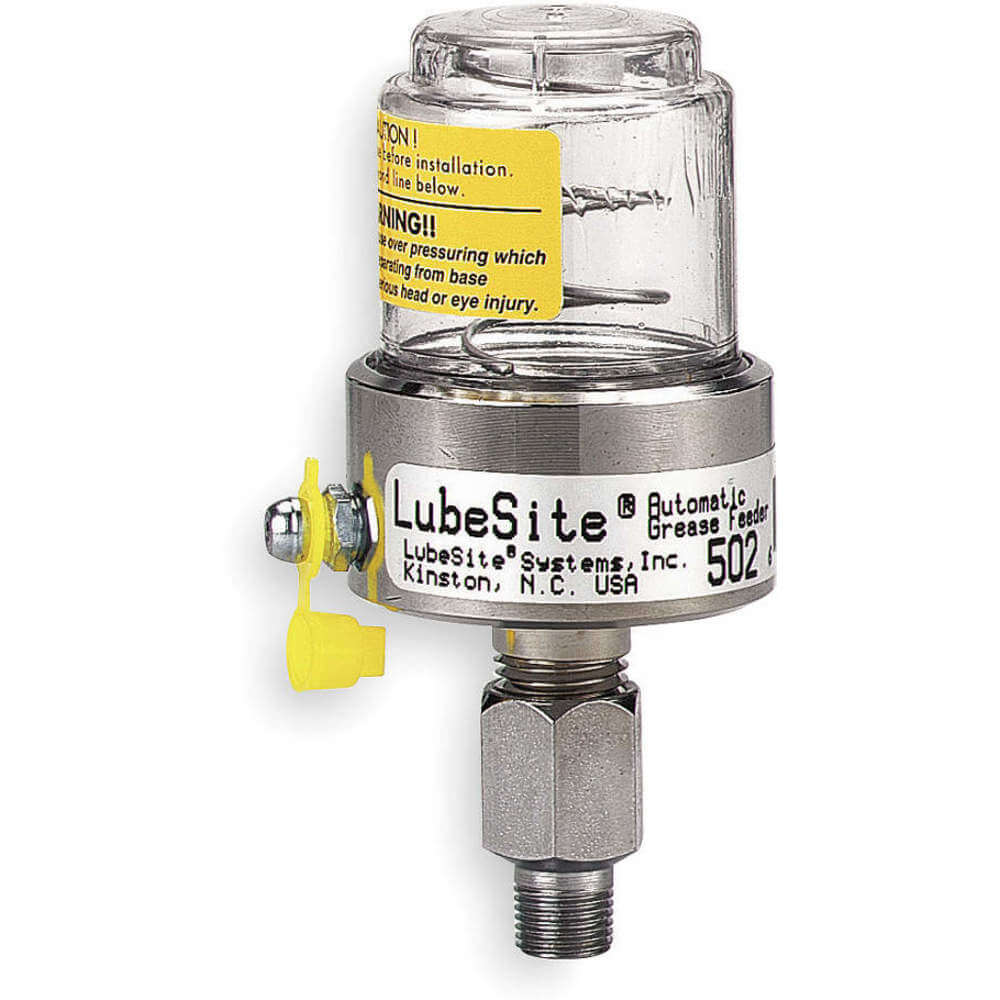

| Item | Grease Feeder |

|---|---|

| Base Material | Aluminum |

| Capacity | 6 oz. |

| Connection Size | 1/8" |

| Connection Type | NPT |

| Delivery Method | Continuous |

| Diameter | 3" |

| Feeder Capacity | 6 fl. oz. |

| Feeder Material | Aluminum |

| Fill | Zerk |

| Finish | Nickel Chrome Plated |

| Flow Rate Adjustability | Non Adjustable |

| Grease Color | Green |

|---|---|

| Includes | Springs |

| Lubrication Point Type | Single |

| Material | Polycarbonate |

| Max. Operating Temperature | 250°F |

| Min. Operating Temperature | -10°F |

| Operating Temp. | -10°F to +250°F |

| Overall Height | 6" |

| Refillable | Yes |

| Spring Force | 13 psi |

| Thread Size | 1/8" |

LubeSite 560 automatic grease feeder is used to lubricate bearing housing at intervals to prevent downtime and reduce manpower. The unit uses silver, red or blue springs for normal, high-tension or low-tension applications, respectively.

| Height (cm) | 11.68 |

|---|---|

| Length (cm) | 22.1 |

| Width (cm) | 11.43 |

| HS Code | 3923900080 |

|---|---|

| Country Of Origin | CN |

| Weight (kg) | 0.675 |

LubeSite 500 Series grease feeders can withstand ambient temperatures ranging from 10 to 250 degrees F.

Yes, LubeSite grease feeders have a refill unit that allows automated lubricant feeding in short intervals, depending on the applications.

LubeSite automatic grease feeder consists of a spring-loaded piston and Viton seal ring. It further has tension springs to maintain a specific pressure range and an O-ring assembly to provide excellent chemical resistance. This compact design allows controlled lubrication to prevent machine downtime, allowing smooth functioning of the equipment.

Tapering metering rods regulate the flow of grease on the bearings.

LubeSite 560 grease feeder is designed for corrosive atmospheres, whereas LubeSite 704 is suitable for high-temperature applications (up to 450 degrees F).

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)