-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

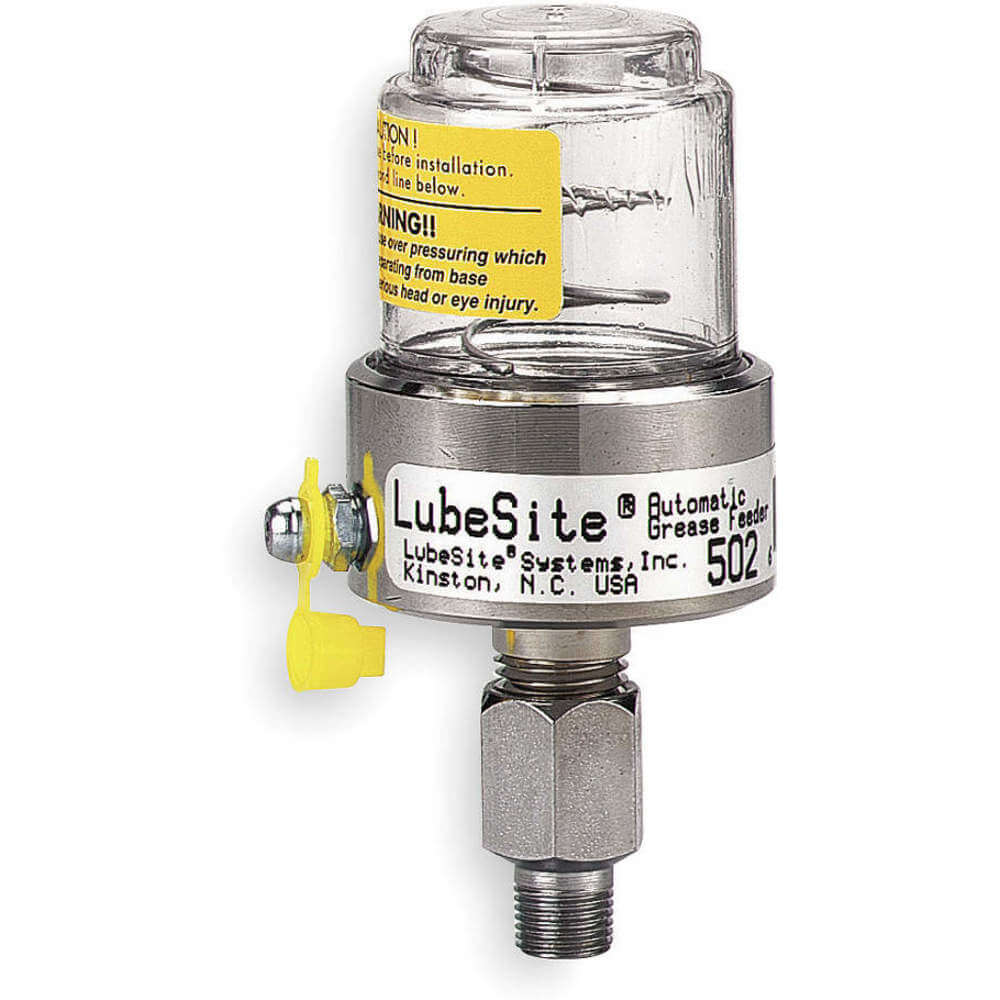

| Item | Grease Feeder |

|---|---|

| Base Material | Aluminum |

| Capacity | 1 oz. |

| Fill | Zerk |

| Finish | Nickel Chrome Plated |

|---|---|

| Material | Polycarbonate |

| Operating Temp. | -10°F to +250°F |

| Thread Size | 1/8" |

LubeSite 502 grease feeder is designed for lubricating reservoirs that are mounted on machines and equipment to automatically dispense grease into critical moving components. This process eliminates the need for manual checks and prevents machine failure due to over-or-under greasing.

| Height (cm) | 5.84 |

|---|---|

| Length (cm) | 9.65 |

| Width (cm) | 8.38 |

| HS Code | 3923900080 |

|---|---|

| Country Of Origin | CN |

| Weight (kg) | 0.18 |

500 Series grease feeders are used in any equipment that has anti-friction oscillating, ball / roller bearings, shielded bearings with seals, bronze bearings and more.

The spring selection depends on the temperature and grease weight. Units are colour coded for use in different applications, such as blue for light, silver for medium, red for heavy and orange for very heavy duty applications.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)