-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

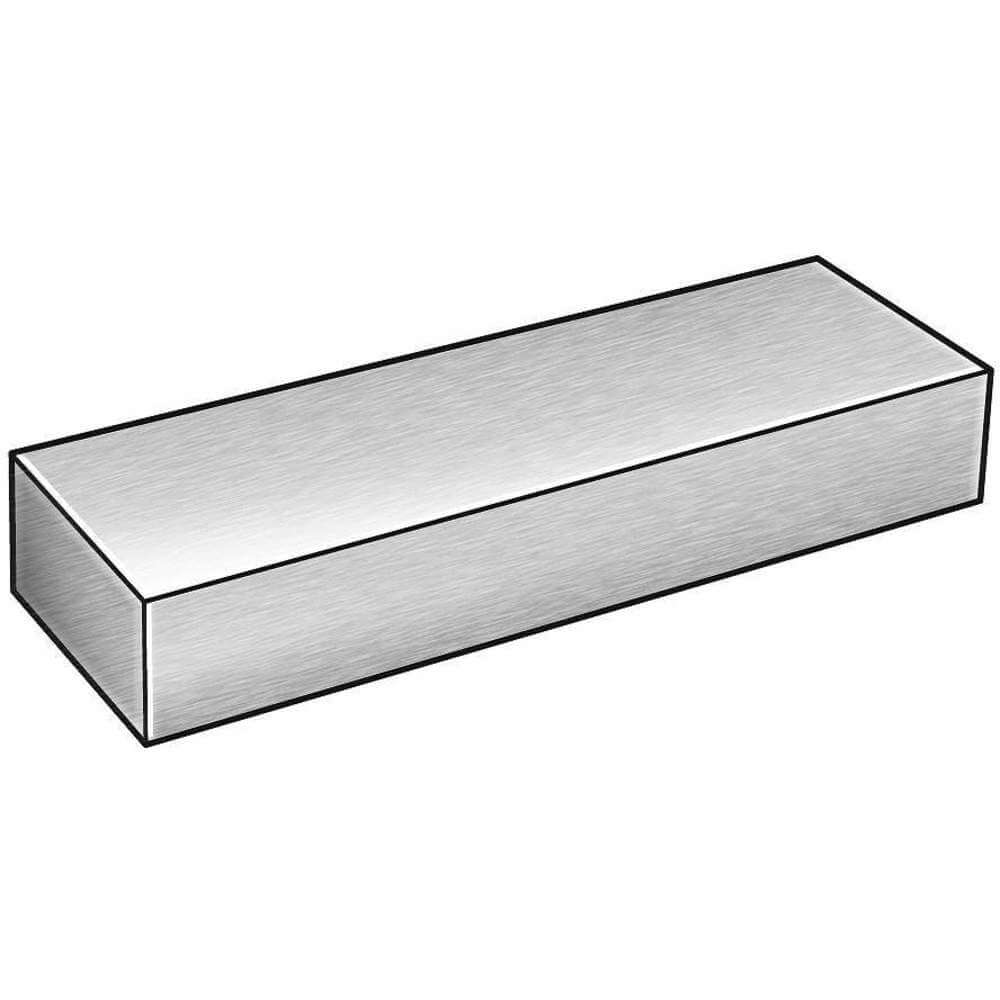

| Item | Control Valve |

|---|---|

| Actuation Type | Solenoid |

| Body Material | Cast Iron |

| Center Position | Closed Center |

| Center Position - Hydraulic Valves | Closed |

| Coil Voltage | 24V DC |

| Electrical Connection Type | Din Without Plug |

| Flow Rate | 20 GPM |

| Gpm @ 3000 Psi | 20 GPM |

| Height | 1.97" |

| Includes Seals | Seals Included |

| Input Voltage | 24V DC |

| Length | 9 1/5" |

| Max. Flow Rate | 80 LPM |

| Max. Pressure | 5000 psi |

| Max. Tank Pressure | 3000 psi |

| Maximum Flow Rate3 | 21.1 GPM |

| Maximum Pressure | 5075 psi |

| Mounting | Subplate-Mounted |

| Nfpa Size | D03 |

|---|---|

| Number Of Positions | 3 |

| Number Of Ways | 4 |

| Operating Temperature - Maximum | 140°F |

| Operating Temperature - Minimum | -13°F |

| Overall Height | 1.97" |

| Overall Length | 9.2" |

| Overall Width | 1.81" |

| Return Mechanism | Spring |

| Return Type - Hydraulic Valves | Spring Centered |

| Seal Material | Nbr |

| Series | D1VW Series |

| Spool Type | Closed |

| Valve Control | Directional Control |

| Valve Type | Solenoid Operated |

| Voltage | 24V DC |

| Width | 1.81" |

| Standards | ISO-4401, NFPA D03 |

Parker D1VW001CNJW hydraulic valve is designed for controlling liquid flow in hydraulic & fluid power pneumatic systems. It also starts or stops the flow of liquid.

| Height (cm) | 4.6 |

|---|---|

| Length (cm) | 23.37 |

| Width (cm) | 5 |

| HS Code | 8481200020 |

|---|---|

| Country Of Origin | US |

| Weight (kg) | 2.232 |

Leaking plugs can cause a malfunction. Because of this, the plugs must be examined for leakage at the scheduled maintenance interval. It is necessary to send the valve back to the manufacturer for repair since leaking plugs might pose a safety risk.

The valve piston returns to the spring centred starting position during a power outage. When using the system or machine, you must determine whether this poses any risks.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)