-

Select Country

- Source Now

Ships within 2 days via

We deliver to your doorstep under DAP terms. Customs clearance is for your account

Business customers can apply for Net 30

No fees, No interest, Fast approval.

Payment

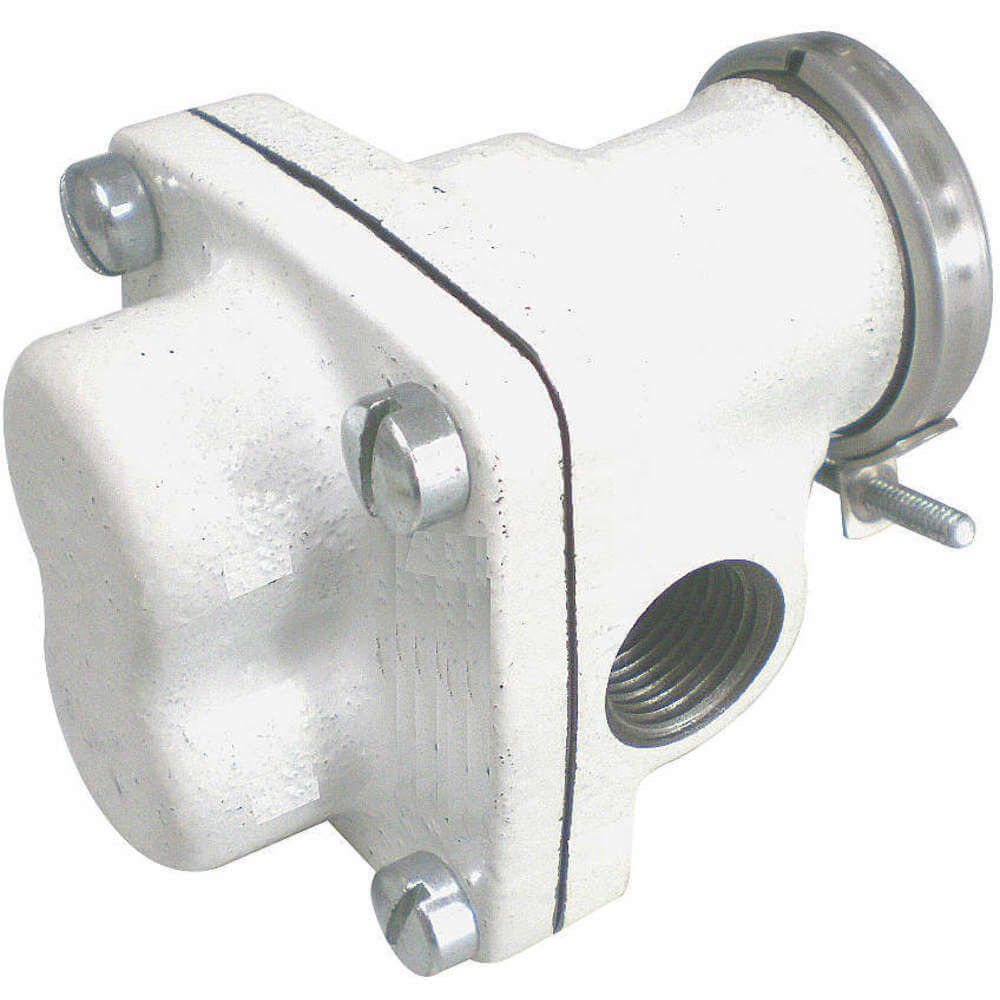

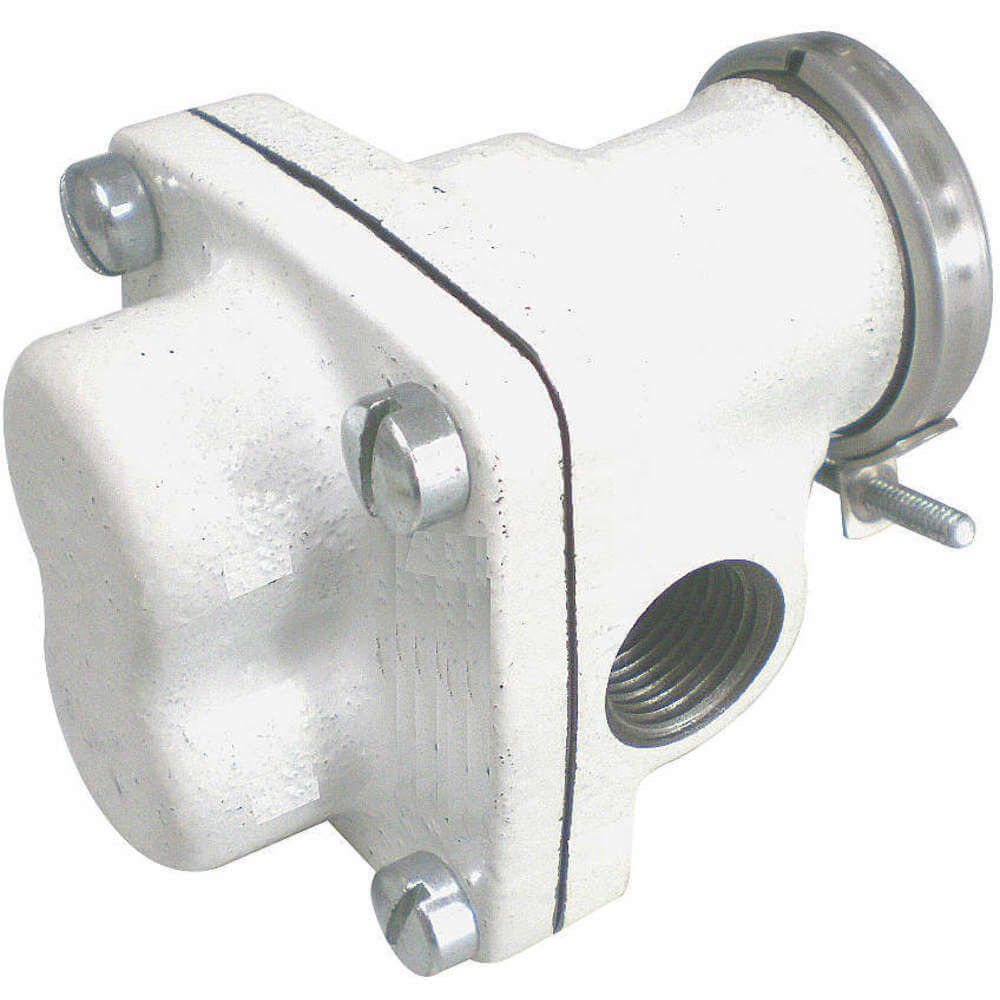

| Item | Rotary Gear Pump Head |

|---|---|

| Amps | 4.1A |

| Body Material | Bronze |

| Compatible Motor Frame | Carbonator Mount |

| Connection Size | 3/8" |

| Connection Type | NPT |

| Design | Close Coupled |

| Duty Rating | Intermediate |

| Flow Rate | 4.4 GPM |

| Flow Rate @ 100 Psi | 3.6 GPM |

| Flow Rate @ 20 Psi | 4.3 GPM |

| Flow Rate @ 40 Psi | 4.2 GPM |

| Flow Rate @ 60 Psi | 4 GPM |

| Flow Rate @ 80 Psi | 3.8 GPM |

| Frame Type | Carbonator |

| Gear Design | Spur |

| Gear Material | Bronze |

| Gear Type | Spur |

| Gpm @ 100 Psi | 3.6 GPM |

| Gpm @ 20 Psi | 4.3 GPM |

| Gpm @ 40 Psi | 4.2 GPM |

| Gpm @ 60 Psi | 4 GPM |

| Gpm @ 80 Psi | 3.8 GPM |

| Gpm @ Freeflow | 4.4 GPM |

| Gpm @ Freeflow @ 1725 Rpm | 4.4 GPM |

| Grade | Grade 304 |

| Height | 3 5/8" |

| Housing Material | Bronze |

| Hp @ 100 Psi | 1/2 hp |

| Hp @ 20 Psi | 1/2 hp |

| Hp @ 40 Psi | 1/2 hp |

| Hp @ 60 Psi | 1/2 hp |

| Hp @ 80 Psi | 1/2 hp |

| Hp @ Free Flow | 1/2 hp |

| Hp @ Free Flow @ 1725 Rpm | 1/2 hp |

|---|---|

| Includes | Relief Valve |

| Length | 7" |

| Max. Motor Speed | 1725 RPM |

| Max. Operating Pressure | 100 psi |

| Max. Pressure | 100 psi |

| Max. Suction Lift | 3.6 ft. |

| Max. Viscosity | 550 SUS |

| Motor Hp | 1/2 hp |

| Motor Mounting Type | Close Coupled |

| Mounting Type | Carbonator Mounted |

| O-ring Material | Buna N |

| Overall Height | 3 3/5" |

| Overall Length | 7" |

| Overall Width | 2 1/2" |

| Port Size | 3/8" |

| Pump Body Material | Bronze |

| Pump Material | Bronze |

| Recommended Motor Hp | 1/2 hp |

| Relief Valve | With |

| Required Horsepower | 1/2 hp |

| Seal Material | Buna N, Carbon, Ceramic, Stainless Steel |

| Seal Type | Mechanical |

| Shaft Dia. | 1/2" |

| Shaft Material | Stainless Steel |

| Shaft Outer Diameter | 1/2" |

| Suction Lift | 3.6 ft. |

| Suction Lift - Maximum | 3.6 ft. |

| Suction Lift @ 1725 Rpm | 3.6 ft. |

| Temp. Range | -20°F to +210°F |

| Type | Intermittent Duty |

| Viscosity - Maximum | 550 SUS |

| Width | 2 1/2" |

Dayton 4KHP9 rotary gear pump head consists of two interlocking gears that rotate to create suction and discharge pressure. It is commonly used in oil & gas, chemical processing, food & beverage and pharmaceutical industries. This gear pump head is useful for transferring viscous or abrasive fluids efficiently. It is a popular choice for uniform fluid transfer in lubrication, fueling and metering processes.

| Height (cm) | 13.97 |

|---|---|

| Length (cm) | 21.84 |

| Width (cm) | 11.94 |

| HS Code | 8413600090 |

|---|---|

| Country Of Origin | IN |

| Weight (kg) | 2.322 |

Fluid viscosity, operating temperature, pressure requirements and speed of rotation can influence the performance of any rotary gear pump head.

To optimise its performance, maintain proper fluid viscosity within the recommended range. Also, monitor and control operating temperature & pressure regularly.

Common issues include leaks around seals, excessive wear on gears & bearings, or cavitation due to improper fluid conditions or operating parameters.

Since you're visiting from the United States, for the best experience and tailored product searches, please use our dedicated U.S. website.

Go to ChatMRO.com (US)